Lab-grown diamonds, also known as synthetic or cultured diamonds, are created in a controlled environment, mimicking the natural conditions under which diamonds are formed deep within the Earth. These man-made gems have gained popularity for their ethical and environmental benefits. In this introduction, we’ll explore the fascinating process of how lab-grown diamonds are made, breaking it down into simple steps for amateurs to understand.

1. Diamond Seed Selection:

The journey of creating a lab-grown diamond begins with selecting a tiny diamond seed crystal. These seeds serve as the foundation for the entire process. They are typically sourced from natural diamonds or previous lab-grown diamonds.

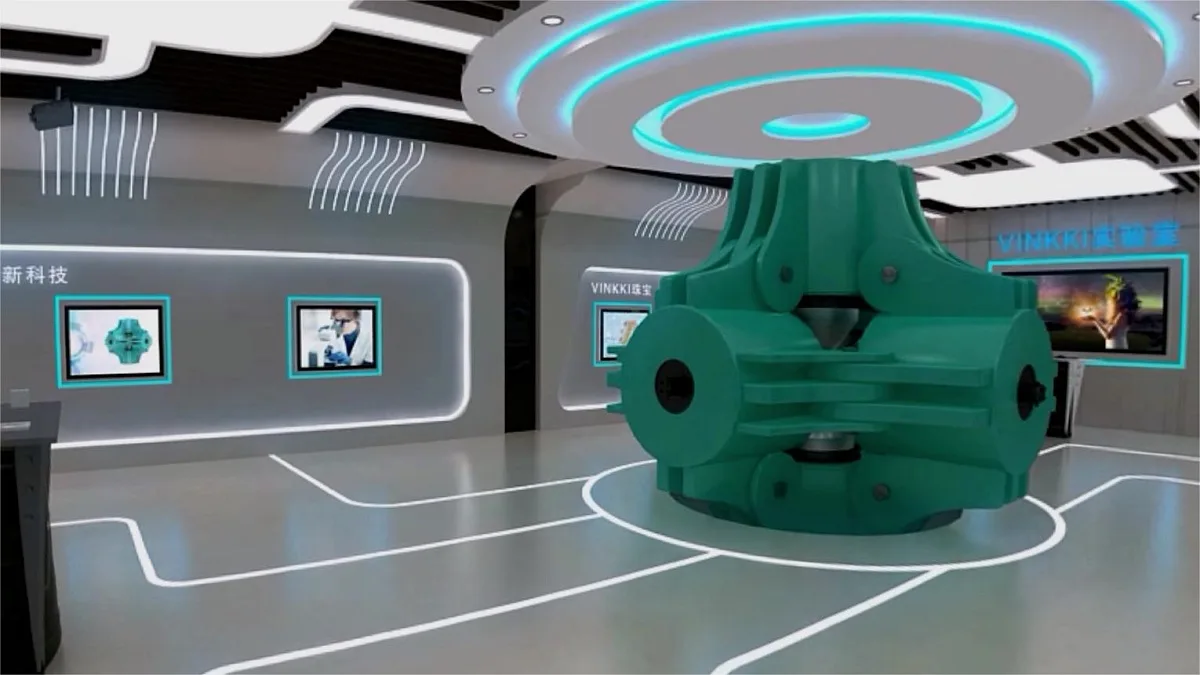

2. High-Pressure High-Temperature (HPHT) Method:

One of the methods to grow lab-grown diamonds is the High-Pressure High-Temperature (HPHT) process. In this method, the diamond seed is placed in a small chamber along with carbon source material, such as graphite. The chamber is then subjected to incredibly high temperatures (over 2,200 degrees Celsius) and pressures (around 725,000 pounds per square inch), simulating the conditions deep within the Earth’s mantle where natural diamonds form.

3. Chemical Vapor Deposition (CVD) Method:

Another popular method for creating lab-grown diamonds is Chemical Vapor Deposition (CVD). In this method, a diamond seed is placed in a chamber filled with a carbon-rich gas, like methane. When the gas is heated, it breaks down, and carbon atoms are deposited layer by layer onto the seed, gradually forming a diamond.

4. Growth and Crystal Formation:

Whether using HPHT or CVD, the diamond seed acts as a template for the new diamond to grow upon. Carbon atoms bond together in a crystal lattice structure, just like in natural diamonds. This process can take several weeks to several months, depending on the desired size and quality of the final diamond.

5. Color and Clarity Enhancement:

After the diamond has grown to its desired size, it may undergo treatments to improve its color and clarity. Some lab-grown diamonds have impurities or defects that can be removed through various techniques to achieve a more desirable appearance.

6. Cutting and Polishing:

Once the rough lab-grown diamond is ready, it is cut and polished by skilled artisans using traditional diamond-cutting techniques. This step is crucial to bring out the diamond’s brilliance and sparkle.

7. Certification:

Just like natural diamonds, lab-grown diamonds can be sent to gemological laboratories for grading and certification. These certificates provide information about the diamond’s quality, including its carat weight, color, clarity, and cut.

In summary, lab-grown diamonds are created through carefully controlled processes that replicate the conditions in which natural diamonds form. These synthetic gems offer ethical, environmental, and economic benefits, making them a fascinating and attractive choice for consumers who value sustainability and beauty.