Chemical Vapor Deposition (CVD) is a widely used method for growing lab-grown diamonds. This process allows for the controlled growth of high-quality diamonds with various industrial and scientific applications. Here’s a detailed explanation of the CVD method for making lab-grown diamonds:

1. Diamond Seed: The process begins with a small, high-quality natural or synthetic diamond seed crystal. This seed crystal serves as the foundation upon which the new diamond will grow. It is typically placed in a controlled environment within a CVD reactor.

2. Reaction Chamber: The CVD reactor is a specialized chamber designed to create the conditions necessary for diamond growth. It is typically a vacuum chamber with precise temperature and pressure control. The chamber contains a source of carbon, usually in the form of a hydrocarbon gas like methane (CH4).

3. Gas Precursor: The hydrocarbon gas, which contains carbon atoms, serves as the carbon source for diamond growth. It is introduced into the reaction chamber.

4. Energy Input: To initiate the diamond growth process, energy is applied to the system. This energy can be supplied through various methods:

- a. Microwave Plasma-Assisted CVD: Microwaves are used to create a plasma from the hydrocarbon gas. The plasma contains highly energetic carbon species, which adhere to the diamond seed and start to form the diamond structure.

- b. Hot Filament CVD: In this method, a heated filament (often made of tungsten) is used to break down the hydrocarbon gas into its constituent carbon and hydrogen atoms. The carbon atoms then attach to the diamond seed and form a diamond lattice.

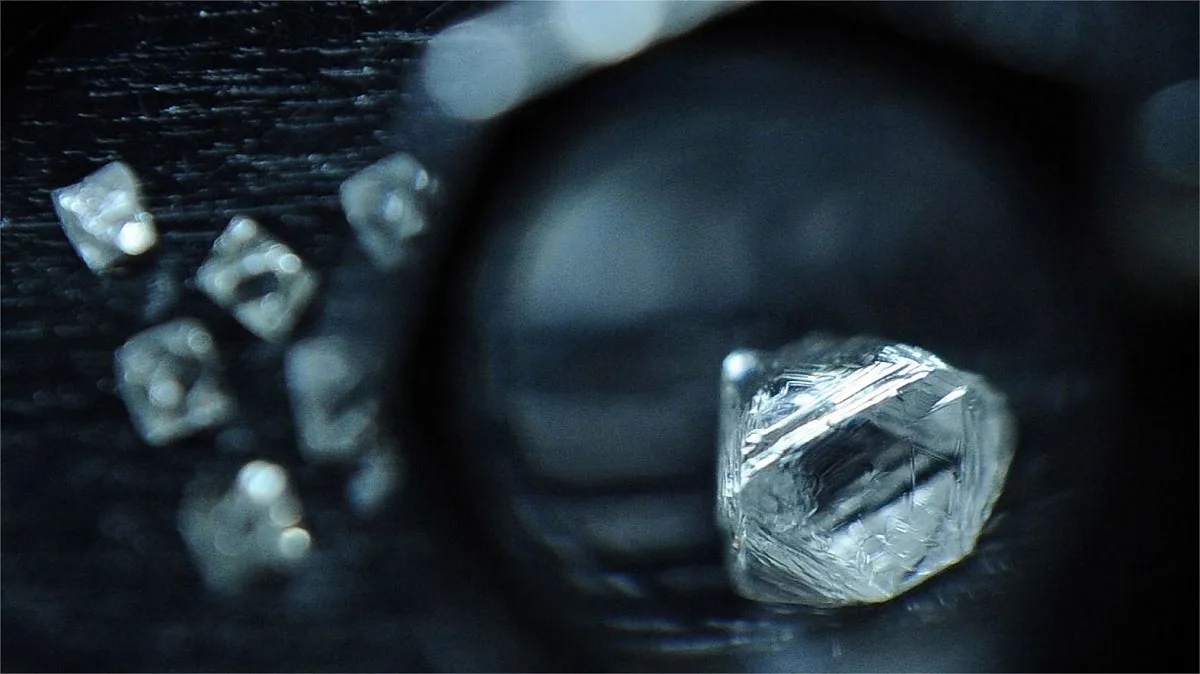

5. Diamond Growth: Once the energy input activates the carbon species, they start to deposit atom by atom onto the diamond seed crystal. This process continues, layer by layer, gradually increasing the size of the diamond. The growth rate can vary depending on factors like temperature, pressure, and gas composition.

6. Control Parameters: The quality and characteristics of the lab-grown diamond can be controlled by adjusting various parameters, including temperature, pressure, gas composition, and growth time. These factors influence the size, purity, and crystal structure of the resulting diamond.

7. Cooling and Cleaning: After the desired diamond size is achieved, the reactor is cooled down to stop the growth process. The newly grown diamond is then carefully removed from the diamond seed.

8. Post-Growth Processing: The lab-grown diamond may undergo further processing steps to enhance its optical and physical properties. These processes can include cutting, polishing, and sometimes heat treatment.

9. Applications: The resulting lab-grown diamond can be used in various industrial and scientific applications, including jewelry, cutting tools, heat sinks, optical components, and research equipment.

One of the advantages of CVD diamond growth is its ability to produce high-quality diamonds with exceptional purity and customized properties. Researchers and manufacturers can fine-tune the growth conditions to tailor the diamonds to specific applications, making CVD-grown diamonds a valuable material in many industries.